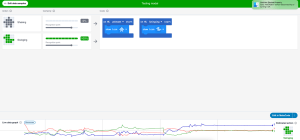

Today in extension, Jennifer from fisher & paykel came back for another session! This time, we were learning about fabrics from our clothing that relates to washing. We also found out the results from last time! There was a graph on the TV, and we found out that the ones with high chemical reaction were the cleanest, and the ones with no chemical action were the dirtiest. This is because even without the chemical action but high mechanical action, the cloth wasn’t actually getting washed. There was no detergent which meant the cloth was actually just sloshing back and forth, but wasn’t actually getting washed. The chemicals help add friction that clean the cloth.

After that we went on to learn about shrinkage and if we’ve ever experience our clothes shrinking before while washing. For me personally, I’ve never experienced it—or that I’m aware of. The only type of shrinking I’ve experienced was through growing bigger. Yeah, my clothes didn’t exactly shrink, but they got smaller. I guess it doesn’t count anyway. A common fibre that shrinks a lot is wool. Today I found out my uniform wasn’t only made out of polyester, but the dominating fibre was wool!

Then we got to see a loom, and found out more about it. A loom is a weaving machine, and you can also use it for wool as well to help weave the wool. There are warp threads and weft threads. Warp threads are the ones running lengthwise on the loom, while the weft threads are the ones moving widthwise (as in the textile).

The pattern for it is up and down. It’s like a wave, and the weft gets woven over and under the warp threads. This creates fabric. And then we all got to get a piece of cotton each since we were also learning about cotton and where it’s from. We learnt that the plant it grows from grows cotton so it can help spread it’s seeds, just like a dandelion. Super fascinating! The cotton was super soft, but it can not stretch. This is because of it’s fibres for it’s plant. So when I tried stretching the cotton, my cotton broke. 🙁

Next we got into a circle, and this time me and Kyaosi got to help. We had to measure the string and then compare it from when we stretch it to it’s normal length. There was actually a change! When the string was stretched out with tension, it got longer by 15 mm. Coolioo!!!!!! Since the original size was 715, and the end was 730.

So then Jennifer put it into a jar of water and it was about the same size, but when it dries it will shrink more. We got to feel 3 different pieces of cotton as well, and they were all different despite having the same fibre.

Thank you Jennifer for this lovely session we had today. I never thought that learning about clothes would be so interesting, but your passion and energy really got my attention. Everything was so fascinating to me! I like the whole part about the loom, and I’m even thinking that someday I might get into science. I had heaps of fun! And I hope you come visit again next time 🙂 Thank you again!!! I couldn’t thank you enough for this amazing session. And thank you once more for taking time out of your day to teach us all about your passions and interests.